Rapid Prototyping

Printrbot + Upgrades [Assembly Instructions]

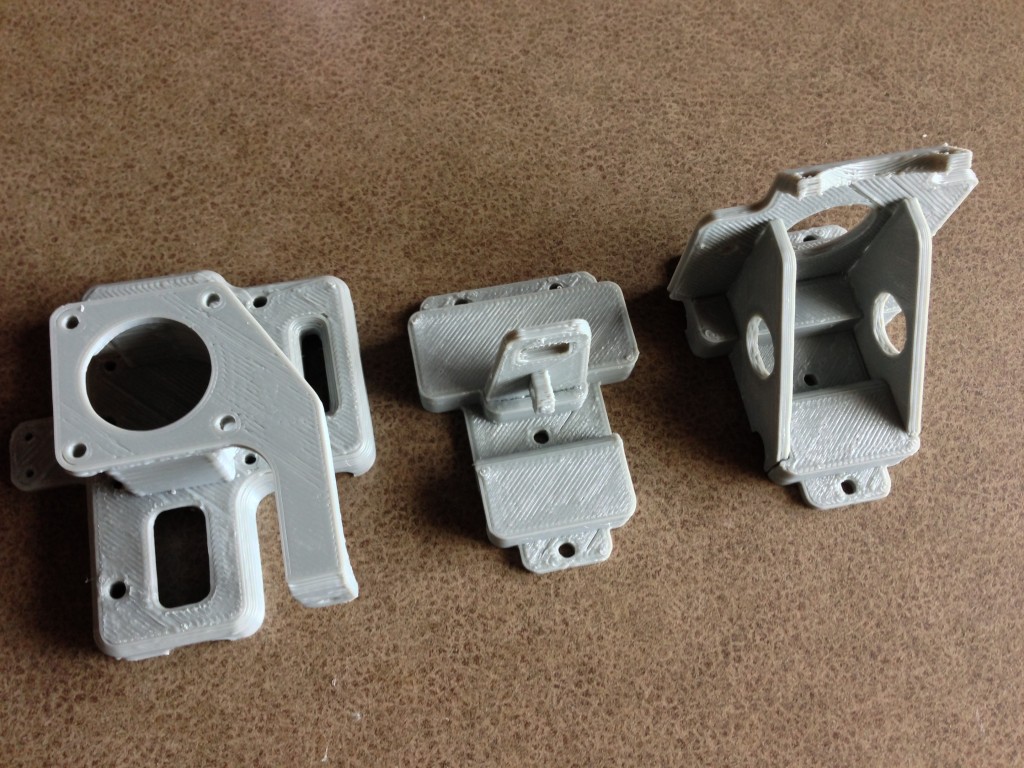

1) After removing the plastic skirt with a hobby knife, use a reamer or file to clean all of the bolt holes.

2) The X-bridge and extruder mount parts print with supporting elements between each bearing sleeve. This plastic must be cut away before installation.

3) Components that are not bolted together should be glued with CA glue (super glue).

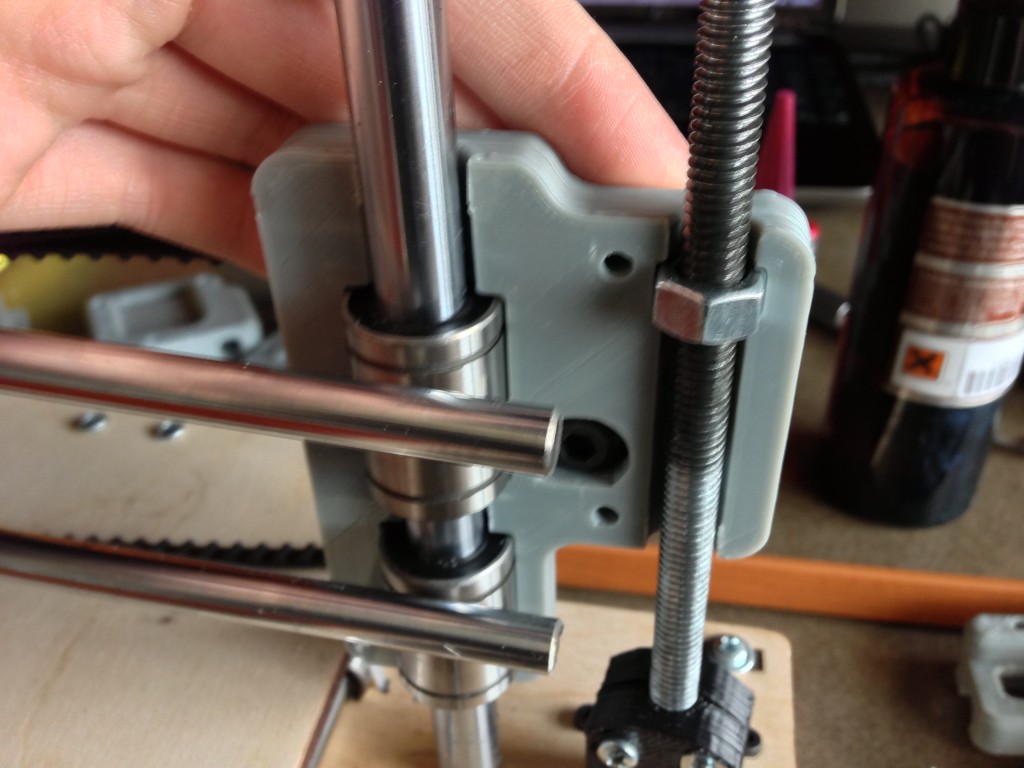

4) The linear bearings should fit snug within the mounts. If there is too much play wrap the outer part of the bearing in vinyl electrical tape. If the bearings are too tight clean the edges with a hobby knife or carefully heat the plastic before inserting the bearings.

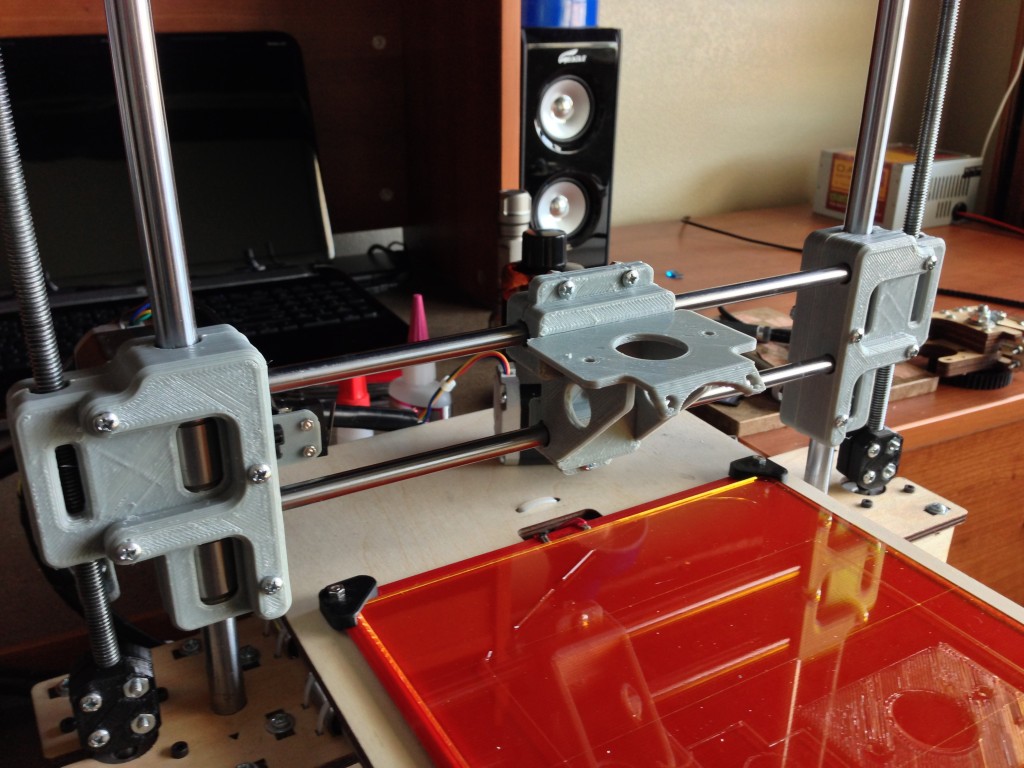

5) Insert the bolt and assemble the x-pulley to the x-bridge.

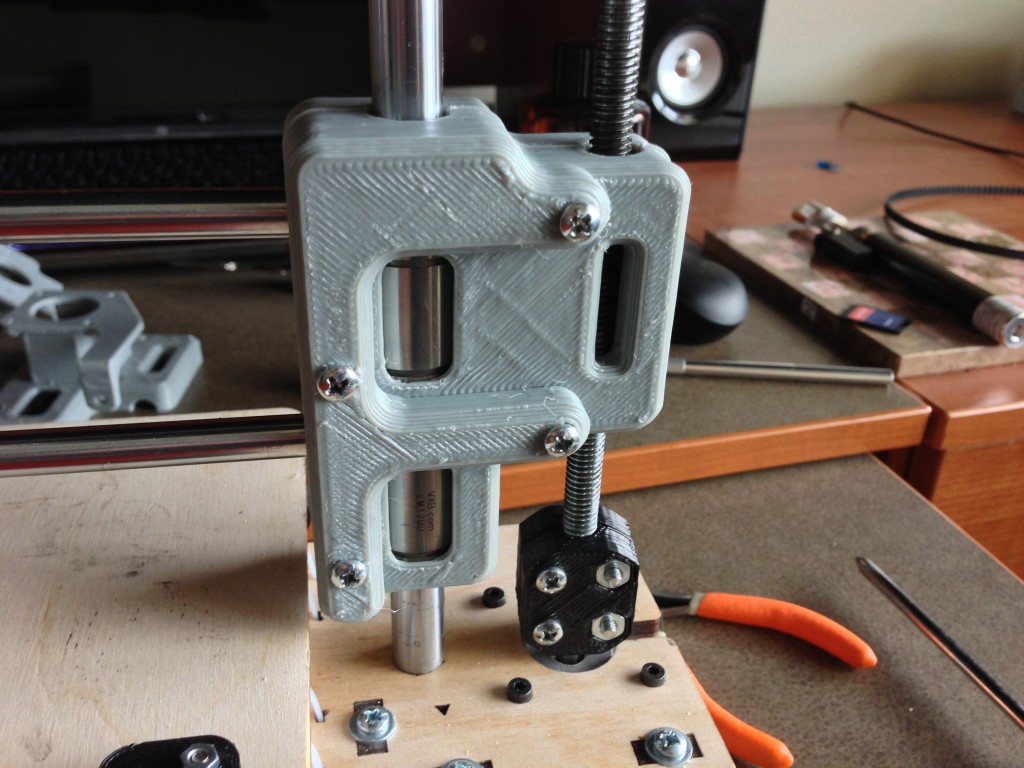

6) Thread the z-nut onto the threaded rod and slide the bearings onto the smoothed rod. Properly align the nut and bearings into the x-bridge before bolting the front plate. If the bearings are too tight clean any plastic from the edges of the sleeves or lightly heat the plastic before inserting the bearings.

7) Bolt all components together using M3 or 1/8″ bolts. Be sure not to over-tighten any of the bolts.

8) Insert the smoothed rods into one end of the x-bridge and slide on the x-carriage before bolting the other side.

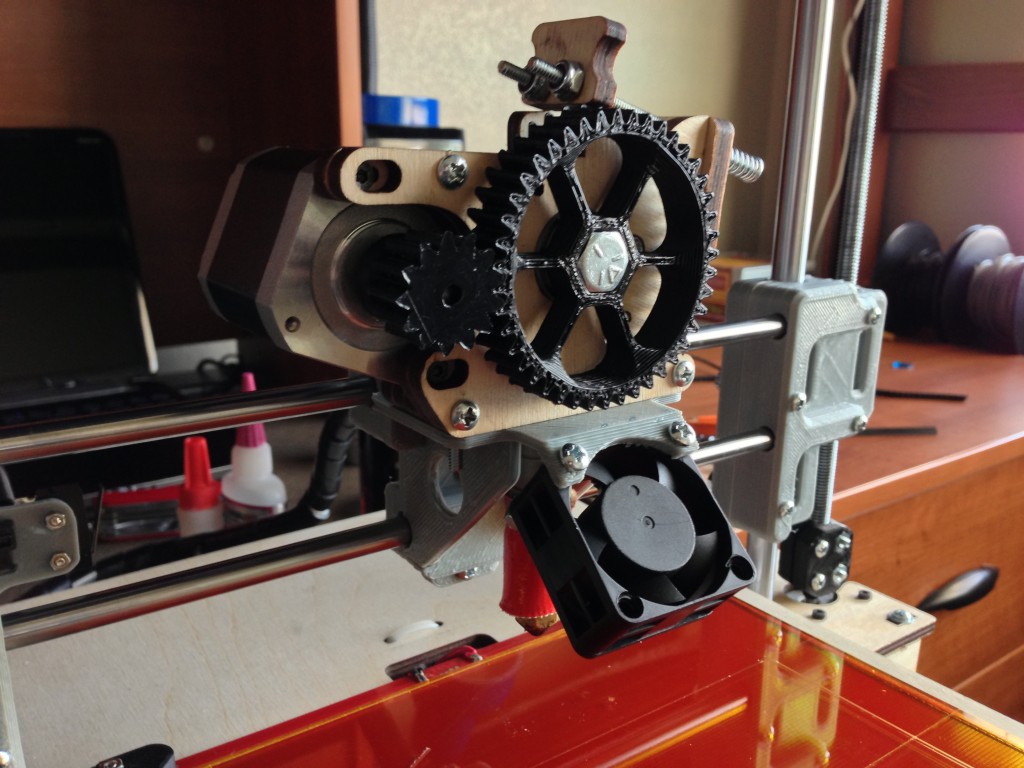

9) Add the extruder and fan to the x-carriage. Tension all belts and secure with cable ties.

10) To adjust the z-endstop, carefully heat the plastic arm until it can be manipulated into alignment. Insert the z-endstop bolt for adjustment of the z-height.